High Nickel Alloy Sheets, Plates & Coils

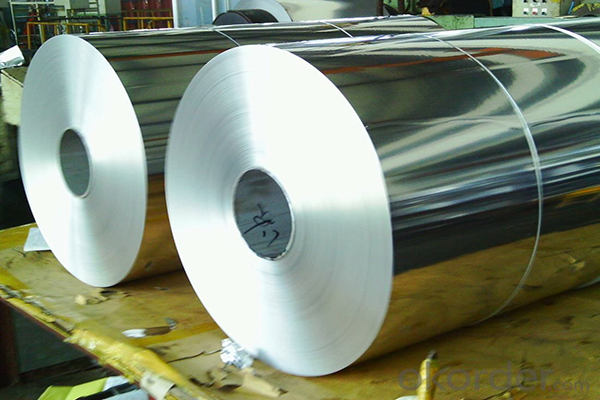

We supplies, exchanges and fabricates a broad assortment of Nickel Alloy Sheets, Plates and Coils to the well – respected clients. These Nickel Plates likewise has some outstanding highlights to offer, for example, fine completion, exact in measurements, unpleasant development, etc. These Nickel Coils are given by us in various particulars at showcase unmistakable rates.

To make these Nickel Alloy Sheets, we result to give that extraordinary quality material that is produced using confided in specialists. We also offer these items in various evaluations, for example, Nickel Sheets, Plates and Coils and Nickel Sheets, Plates and Coils. In the mean time, these Nickel Alloy Coils are likewise being offered in various sizes and shapes to our clients, where we additionally offer the equivalent, best case scenario costs. Likewise, both expanding temperature and air circulation in our Nickel Alloy Plates will quicken consumption.

The utilization of these Nickel Slatting Coils in air – soaked hydrochloric corrosive above room temperature is typically constrained to groupings of under 3 % – 4 %, yet totally air immersed arrangements are not normally utilized in industry. Pollutions, for example, iron erosion in our Nickel Perforated Coils can meddle by methods for the improvement of such a film. Both air circulation and expanding temperatures increment consumption rates with the goal that the chief utilization of these Nickel Alloy Slatting Coils in sulphuric corrosive is in non – circulated air through arrangements close to room temperature.

Specifications:

| Specifications | : | ASTM / ASME SB 168 |

| Size | : | 1000 mm x 2000 mm, 1220 mm x 2440 mm, 1500 mm x 3000 mm, 2000 mm x 2000 mm, 2000 mm x 4000 mm |

| Thickness | : | 0.1mm to 12 mm Thk |

| Form | : | Coils, Foils, Rolls, Plain Sheet, Shim Sheet, Strip, Flats, Blank (Circle), Ring (Flange) |

| Finish | : | Hot rolled plate (HR), Cold rolled sheet (CR), 2B, 2D, BA NO(8), SATIN (Met with Plastic Coated) |

| Hardness | : | Soft, Hard, Half Hard, Quarter Hard, Spring Hard etc. |

Applications

- Off-Shore Oil Drilling Companies

- Power Generation

- Petrochemicals

- Gas Processing

- Specialty Chemicals

- Pharmaceuticals

- Pharmaceutical Equipment

- Chemical Equipment

- Sea Water Equipment

- Heat Exchangers

- Condensers

- Pulp and Paper Industry